Welcome to Daneshmand Control Fidar

We expect to play an effective role in enhancing the level of automation and information technology in the country's industry. By understanding the correct concepts in process control, digital transformation, and smartization, we aim to improve the qualitative and quantitative efficiency of production in industries. Additionally, we seek to enable automated access for managers to key production process information, thereby playing a significant role in making effective decisions aligned with company objectives.

- Creativity

- Perseverance

- Ability

Our ability

- Comprehensive Industrial Automation Solutions: Design, manufacturing, procurement engineering, implementation, programming, and commissioning of control and monitoring systems for steel, petrochemical, water, energy, and production industries.

- Design and Implementation of SCADA Systems for Electrical and Fluid Stations: Data collection, control, and precise monitoring in substations, transmission lines, power modules, pumping stations, and treatment plants.

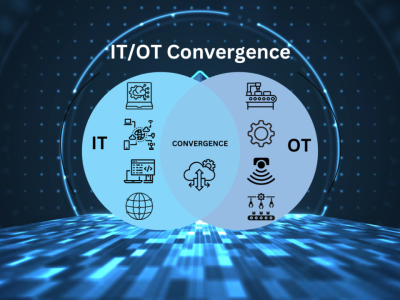

- Development and Integration of IT and OT Systems: Secure and stable connection between IT (Information Technology) and OT (Operational Technology) networks, based on industrial architecture principles, with certification from Iran’s Cybersecurity for Production and Information Exchange Organization (AFTA) – https://afta.gov.ir.).

- Industrial Cybersecurity: Design and implementation of security layers to protect industrial data, prevent intrusions, and maintain OT network stability.

- Integration of Plant-Wide Industrial Supervision Systems: Visualization of the production cycle from raw material input to finished product, with dashboard functionalities on a centralized video wall.

- Specialized Implementation of Level 2 Industrial Automation Systems: Design and implementation of advanced systems to monitor and optimize production line performance by collecting data from Level 1 and sending corrective instructions. These systems include modules for: o Downtime management and analysis o Production sequence optimization o Product traceability o Calculation of Key Performance Indicators (KPIs) o Report generation Data can also be exchanged with Level 1 to adjust process parameters in real-time to improve productivity and reduce operational losses.

- Designing and implementing a program to display the factory's industrial monitoring system with dashboarding features and the production cycle from the arrival of raw materials to the final products in the central video wall.

- Professional and Flexible Team: A team of experienced engineers capable of quickly adapting to large-scale projects, offering long-term technical support.

- Competitive Pricing and Regional Cultural Understanding: Delivery of specialized services at reasonable costs, with a precise understanding of country-specific conditions.

Completed projects

0

+

Project in progress

0

+

Fidar scientist customers

0

+

Your rating for us:

Cooperate with Daneshmand Control Fidar

Daneshmand Control Fidar is always looking for talented professionals. View our current job openings and submit your resume.